Exploring the Future of Machinery and Equipment: Innovations That Will Transform Industries

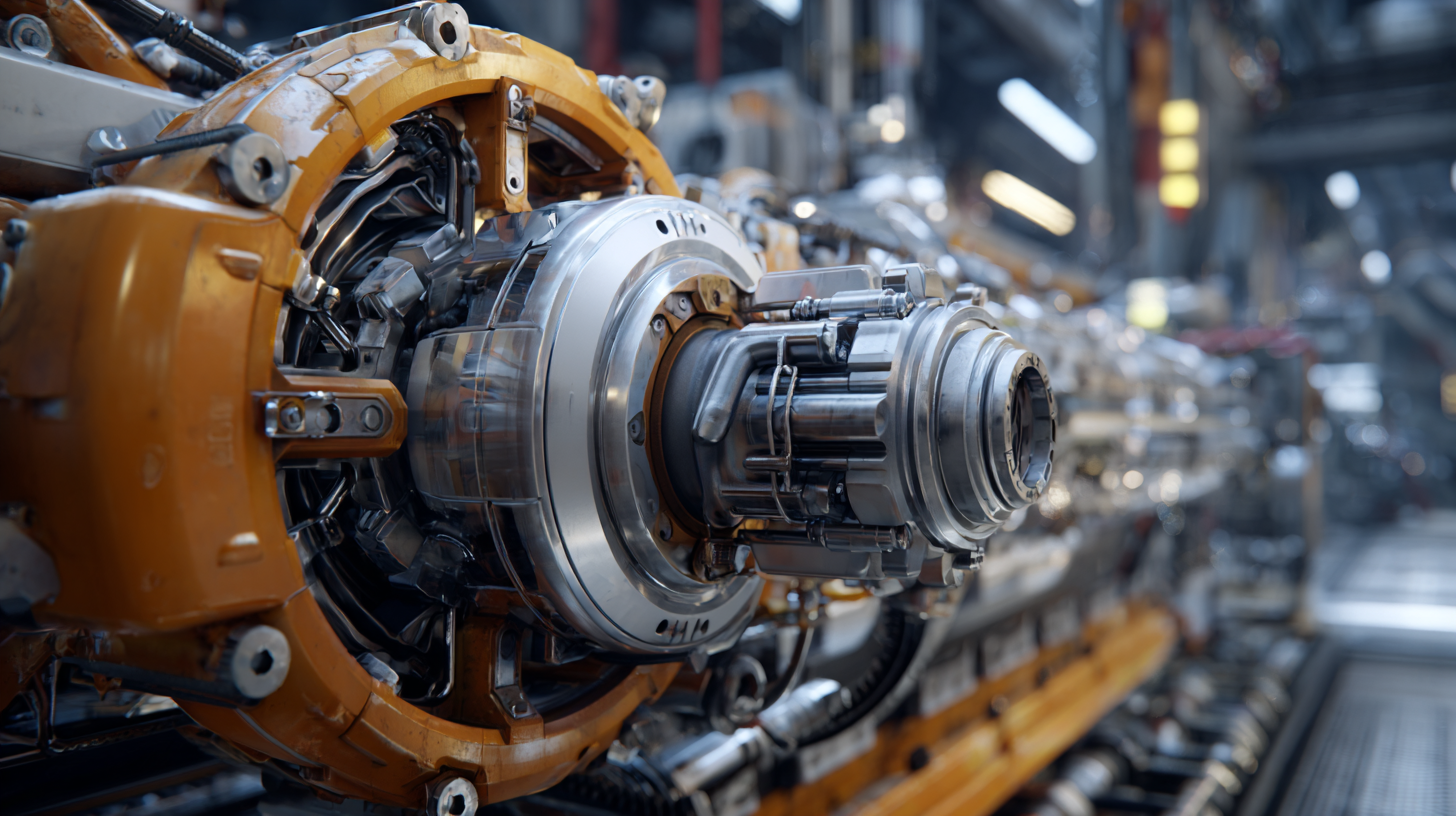

In the rapidly evolving landscape of global industries, the future of machinery and equipment stands as a beacon of innovation and transformation. Renowned expert Dr. Emily Hargrave, a leading figure in industrial engineering, emphasizes the significance of embracing technological advancements, stating, “The integration of smart technologies in machinery and equipment is not just a trend; it's a necessity for industries aiming to thrive in the 21st century.” This statement encapsulates the urgency for businesses to adapt to the changing demands of the market, where efficiency and precision define success.

As we dive into the exploration of the top five innovations poised to reshape the machinery and equipment sector, it is crucial to recognize the pivotal role that automation, artificial intelligence, and sustainable practices will play. These advancements not only enhance operational efficiency but also foster a more resilient supply chain capable of responding to unforeseen challenges. With industries prioritizing sustainability, the development of eco-friendly machinery and equipment has entered a new era, where environmental impact is as important as productivity.

Ultimately, the future of machinery and equipment lies in the hands of those willing to innovate and adapt. The following sections will delve deeper into each transformative trend, shedding light on how they will redefine operational paradigms and drive the next industrial revolution.

Analyzing the Impact of AI and Machine Learning on Manufacturing Efficiency

The advent of artificial intelligence (AI) and machine learning is revolutionizing manufacturing efficiency, significantly transforming production processes across various industries. AI algorithms can analyze vast amounts of data in real-time, enabling manufacturers to predict equipment failures, optimize maintenance schedules, and enhance the overall equipment effectiveness (OEE). This predictive capability not only reduces downtime but also minimizes costs associated with unplanned repairs, thereby streamlining operations.

Furthermore, machine learning models enable adaptive manufacturing, where machines learn from historical data and continuously improve their performance. This allows for smarter automation, where robotic systems can adjust their processes dynamically in response to varying production demands. As a result, manufacturers can achieve greater flexibility and scalability, accommodating market fluctuations without sacrificing quality. The integration of AI technologies facilitates not only enhanced productivity but also fosters innovation in product development, paving the way for smarter, more efficient factories that will lead the industry into the future.

Exploring the Future of Machinery and Equipment: Innovations That Will Transform Industries

This chart illustrates the expected improvements in manufacturing efficiency through the adoption of AI and Machine Learning technologies over the next five years. The data shows a projected percentage increase in efficiency across several manufacturing sectors.

The Role of IoT in Enhancing Equipment Maintenance and Downtime Reduction

The Internet of Things (IoT) is paving the way for substantial advancements in equipment maintenance within various industries. By enabling interconnected devices to collect and exchange data in real-time, IoT facilitates predictive maintenance practices that reduce downtime significantly. This technology allows companies to monitor the health and performance of their machinery continuously, empowering them to address potential issues before they escalate into costly failures. As a result, organizations can optimize their maintenance schedules and allocate resources more effectively.

In addition, the impact of IoT extends into the healthcare sector, where it is revolutionizing patient care and operational efficiency. By integrating IoT devices, healthcare providers can track vital signs remotely, ensuring timely interventions and personalized treatment plans for patients. Furthermore, the analysis of data generated from these devices can streamline workflows and improve resource management, ultimately leading to better healthcare outcomes. As industries continue to adopt IoT solutions, the role of connected technologies in enhancing equipment maintenance and overall productivity will undoubtedly become increasingly prominent.

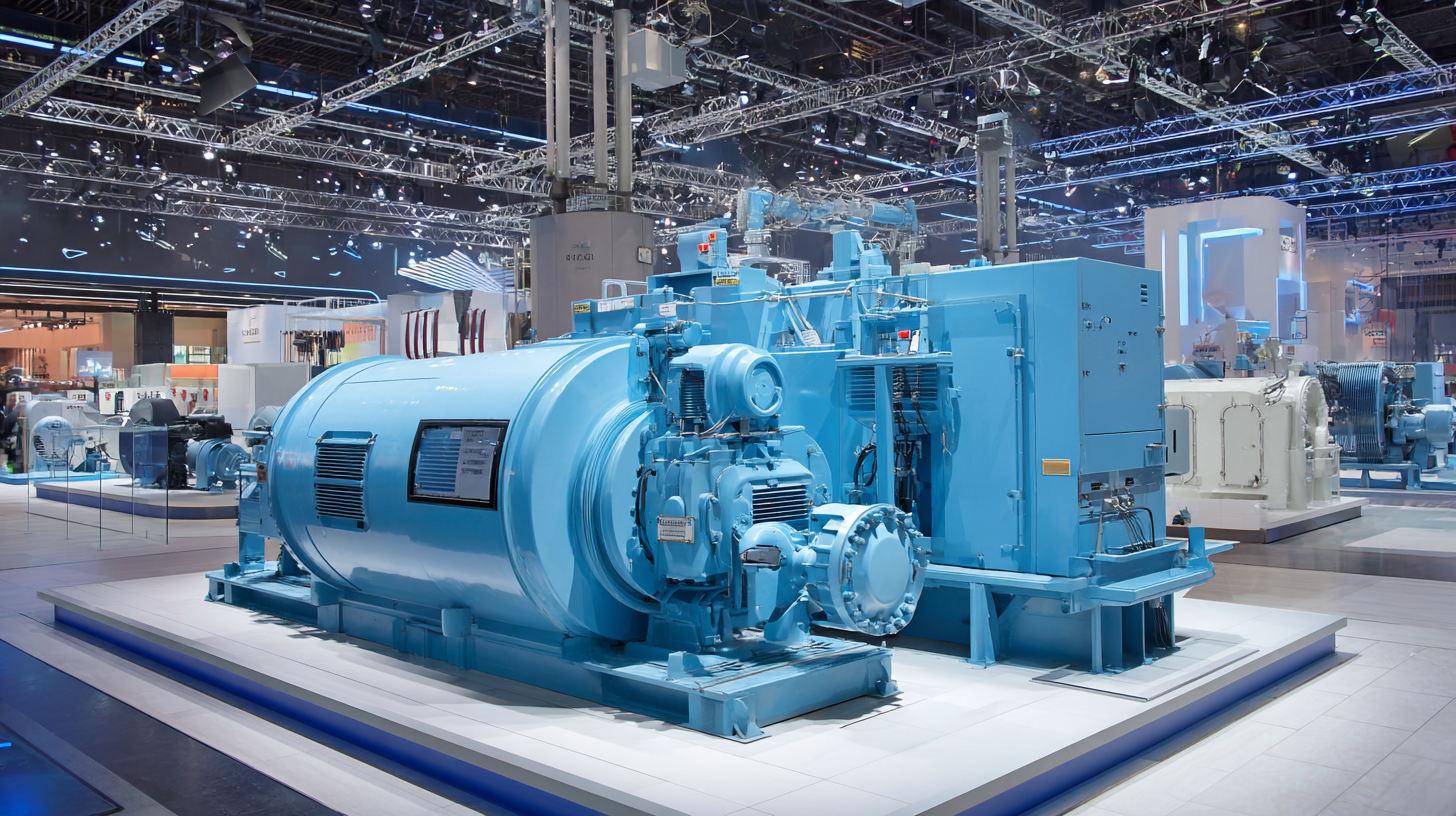

Sustainable Innovations: How Renewable Energy is Reshaping Machinery Design

The future of machinery and equipment is increasingly being influenced by sustainable innovations, particularly through the integration of renewable energy sources in design and functionality. As industries worldwide strive to reduce their carbon footprint, the push for machinery that operates effectively on renewable energy has gained significant momentum. This transition not only helps in adhering to environmental regulations but also positions companies as leaders in sustainable practices, enhancing their competitive edge in the marketplace.

The future of machinery and equipment is increasingly being influenced by sustainable innovations, particularly through the integration of renewable energy sources in design and functionality. As industries worldwide strive to reduce their carbon footprint, the push for machinery that operates effectively on renewable energy has gained significant momentum. This transition not only helps in adhering to environmental regulations but also positions companies as leaders in sustainable practices, enhancing their competitive edge in the marketplace.

Moreover, the incorporation of technologies such as solar panels, wind turbines, and biofuels into machinery design presents new opportunities for efficiency and cost savings. For instance, construction equipment powered by solar energy can operate in remote areas without the need for traditional fuel supplies, leading to cost reductions and a smaller environmental impact. These innovations are poised to not just revolutionize the design of machinery but also redefine operational logistics across various industries, fostering a future where sustainability and productivity go hand in hand.

Exploring 3D Printing: Revolutionizing Production Processes Across Various Industries

3D printing is at the forefront of industrial innovation, enabling significant changes to production processes across various sectors. According to a report by Wohlers Associates, the global 3D printing industry is expected to reach $34.8 billion by 2024, driven by advancements in printing technologies and materials. This revolutionary manufacturing method allows companies to reduce waste, shorten production times, and create complex geometries that were previously impossible with traditional methods. Industries such as aerospace, automotive, and healthcare are rapidly adopting 3D printing to enhance their capabilities, improve product quality, and decrease lead times.

Tip: To fully utilize 3D printing, businesses should invest in training their workforce and integrating new software solutions that optimize design and production processes. Furthermore, fostering collaboration between engineering and production teams can lead to innovative applications of 3D printing technology.

As 3D printing continues to evolve, it is reshaping the supply chain dynamics. A study by Deloitte indicates that 60% of manufacturers believe 3D printing will fundamentally alter their supply chains by 2025. The ability to produce on-demand parts reduces the need for large inventories, ultimately leading to cost savings and increased flexibility. Companies are encouraged to stay abreast of technological advances in materials and printing techniques to remain competitive in this fast-evolving landscape.

Tip: Organizations should consider conducting pilot projects to explore the potential of 3D printing for specific applications, allowing them to experiment and adapt strategies before full-scale implementation.

Cybersecurity Strategies for Protecting Smart Machinery in an Evolving Landscape

As smart machinery continues to revolutionize multiple industries, the need for robust cybersecurity strategies becomes increasingly critical. With the integration of IoT and AI technologies, machinery and equipment are now more interconnected than ever, making them potential targets for cyberattacks. Protecting these systems demands a proactive approach that includes risk assessment, regular software updates, and implementing multi-layered security protocols. Organizations must recognize that safeguarding smart machinery is not just about preventing unauthorized access but also includes ensuring data integrity and privacy throughout the machinery's lifecycle.

Moreover, as the landscape of cybersecurity evolves, adaptive strategies are essential. This could involve investing in advanced threat detection systems that utilize machine learning to identify unusual patterns and potential threats in real time. Collaborating with cybersecurity experts and industry leaders to share best practices will also play a crucial role in fortifying defenses against emerging threats. Companies must prioritize training employees on cybersecurity awareness to create a culture of vigilance and responsibility in protecting smart machinery. By implementing these comprehensive strategies, industries can effectively navigate the complexities of cybersecurity in a rapidly advancing technological environment.